Ready for AI

Powerful, freely programmable smart cameras with NVIDIA Jetson modules. Baumer presents the AX smart cameras,

its first industrial-grade smart cameras that combine the market-leading NVIDIA Jetson modules with powerful

Sony CMOS sensors to create a compact, flexible, and freely programmable image processing platform for

AI‑applications.

Read More

Small pixels for higher image quality

Compact 29×29 mm industrial cameras with Sony Pregius S sensors up to 24 MP. Baumer is expanding its CX series

with the 4th Sony CMOS sensor generation Pregius S with up to 24 megapixel resolution. Thanks to a pixel size of

mere 2.74 µm and backside illumination pixel architecture, the camera has a very compact design (29 × 29 mm) and

offers very high resolutions with excellent image quality and improved sensitivity for stable image evaluations.

Read More

Image processing in a new dimension

Spectra PowerBox 5000: Scalable high-end GPU computing system. Modern processes in industrial AI and machine

vision are closely linked to image processing. This requires industrial PC systems with CPU and GPU performance

large enough to process the tasks in real time.

Read More

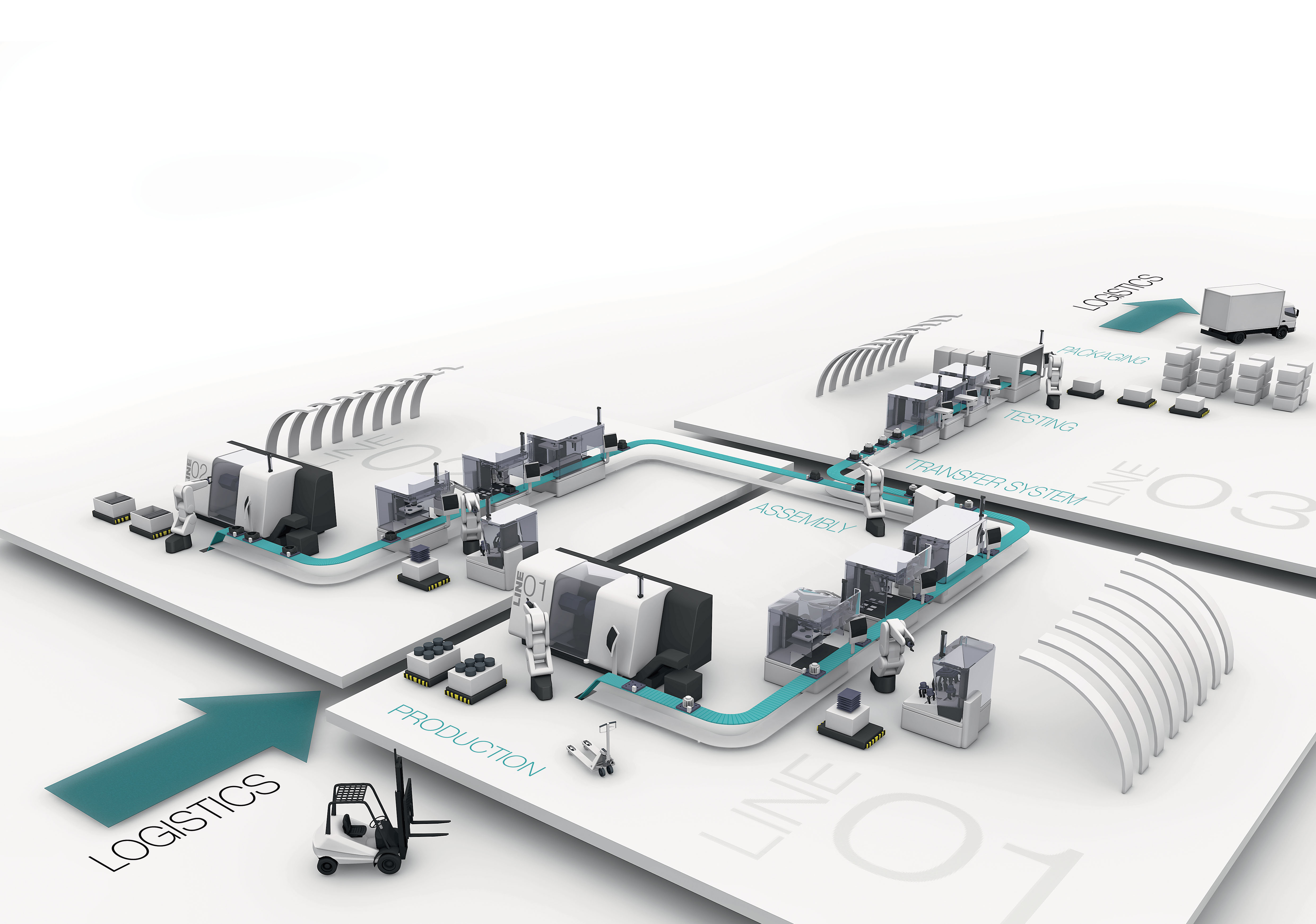

Human Digital Twin: The digital counterpart to the human worker

Wearables from ProGlove make humans a driving force of Industry 4.0 and digital transformation. The Digital Twin

is a digitized model that maps the physical characteristics of a production environment as well as the

processes. But this mapping has its limitations, as it only includes data from machines and not from humans. At

the same time, human employees will continue to play an important role in the Fourth Industrial Revolution, also

known as Industry 4.0. The challenge lies in combining the...

Read More

Cameras, image sensors, photodiodes based on InGaAs

Hamamatsu Photonics provides InGaAs solutions covering the visible (VIS), near infrared (NIR), and short

wavelength infrared (SWIR) regions. Our solutions fulfill different applications including spectrometers for

spectrometry, scientific cameras for microscopy, and machine vision for industrial imaging. Also, we provide

driver modules and evaluation boards to decrease your design time. Customizations are available for specific

applications and requirements.

Read More

3D ToF sensors for touchless machine operation and autonomous robots

Touchless and thus hygienic operation of machines and measuring equipment to ensure social distance as well as

the control of autonomous robots requires powerful sensors. The 3D ToF sensor from Hamamatsu measures the

distance to an object using the indirect ToF method (Time of Flight).

Read More

ProGlove enables TTI Europe saving more than 10 hours per day

The ProGlove smart glove scanner has been in use for a number of years at TTI Europe, based in Maisach near

Munich. Since deploying the ProGlove barcode scanners, the electronics distributor has unlocked multiple

productivity efficiencies through its ergonomic handling, reliability and robust industrial design. Overall, the

time saved due to the introduction of streamlined barcode scanning exceeds ten hours per day.

Read More

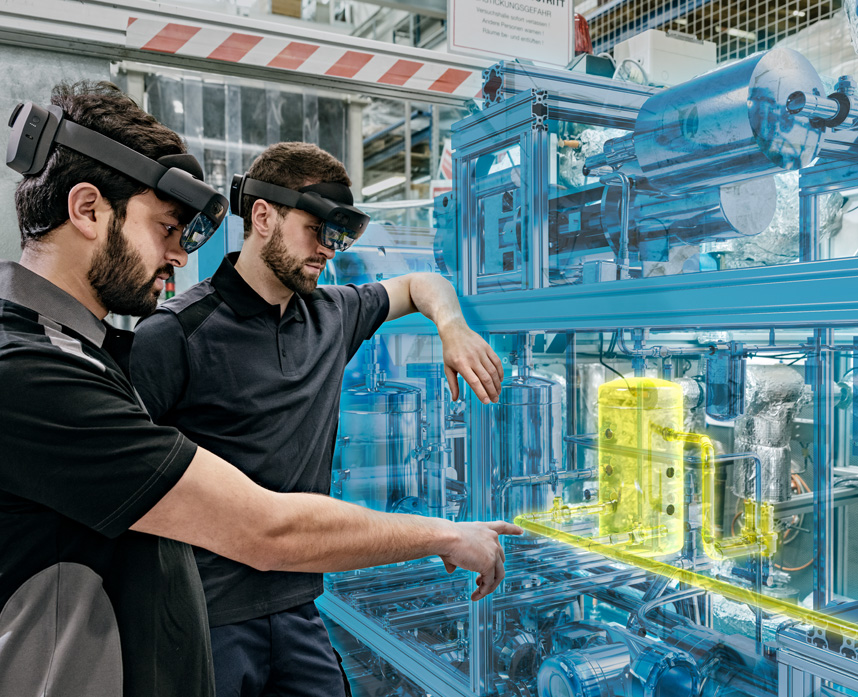

Augmented Reality as Driver of the Automation Industry

Automation processes in the industrial sector are becoming faster, more efficient, and more intelligent with the

development of new technologies. But the things which add value to companies in this industry often present

challenges for the internal employees who need to oversee, monitor, manage, develop, or repair these automated

and fully optimized processes. With Augmented Reality (AR), workers can be effectively supported along the

entire value chain to ensure the best possible human-machine...

Read More

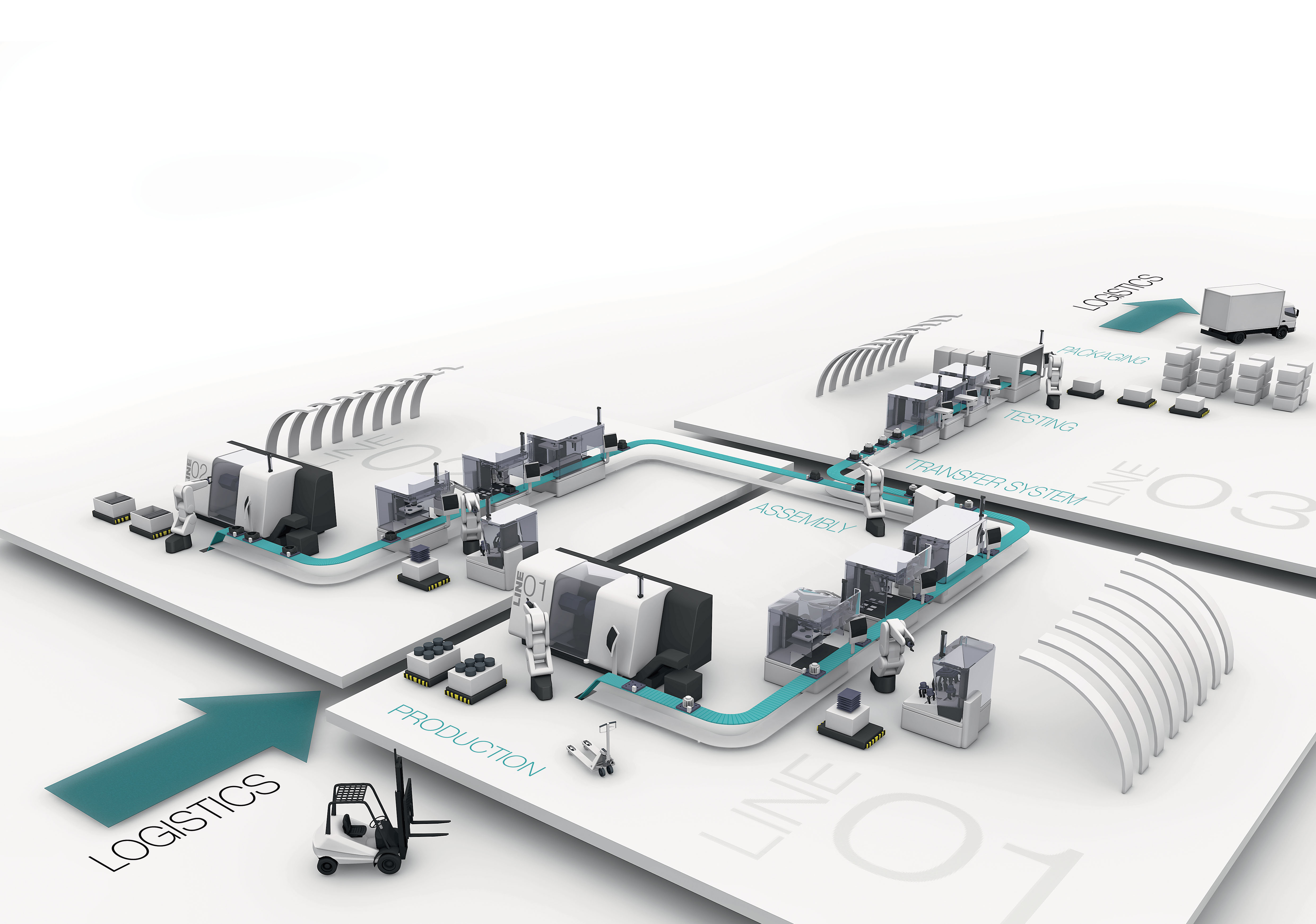

Balluff SmartCamera: Intelligent data management contributes to stable production processes

Industry 4.0 – the smart, adaptive factory with short retooling times and decentralized control – aims to

generate the most comprehensive data possible within a highly automated process in real-time and provide the

most varied instances possible. This status information in the form of process data for control and monitoring

of sequences and product data for traceability and quality verification form an objective basis for making

decisions in order to take early measures for process optimization.

Read More

3D multi-stereo sensor with large measuring field

With embedded technology and a particularly large field of view, a new 3D sensor from ISRA VISION offers short

scanning times and fast data availability, making it ideal for use directly on the production line.

Read More

Deep learning-based image analysis

Cognex VisionPro ViDi enables deep learning-based machine vision for automatic identification, inspection and

classification.

Read More

Robot systems: workpiece handling with vision

It started with a blank. But how does the workpiece get onto the line or into the machine? Depending on the

state it is delivered in, this task can quickly become very complex. Reliable 3D object detection systems

optically capture and evaluate data. Liebherr works with a variety of 3D vision systems to match the

requirements and smoothly handles the supply of every haphazardly stored part with process precision.

Read More

Barcode verification with Cognex verifiers

The verification of barcodes helps ensuring the readability of the barcode throughout the complete supply chain.

Barcode verification is the process of grading the quality of barcodes. A barcode verifier assigns an overall

grade to a code based on measurements of several quality parameters. Depending on the code type they apply

different national and international standards.

Read More