Advanced industrial motion control

Dynetics presents the SOMANET servo drives from Synapticon: Integrated motion for robotics, machine building and

autonomous industrial systems. Synapticon, based in Schönaich near Stuttgart, Shanghai and Redwood City (Silicon

Valley), is reshaping the world of motion control for robotics and machines at the point of motion. The company

is introducing an entirely new approach to motion axes by integrating formerly discrete components such as

motors, drives, sensors and gears into seamless units,...

Read More

Bosch Rexroth performs handling tasks mechatronically – the quick and easy way

An intelligent multi-axis system – quicker, more convenient and more cost‑effective than ever before: Bosch

Rexroth now makes this possible with the new Smart Function Kit for Handling. After the Smart Function Kit for

Pressing and Joining, the linear motion technology experts are expanding the Smart MechatroniX solution platform

with a second predefined subsystem which can be operated intuitively.

Read More

AGV solution in automotive environment

In the body shop of the international automobile premium manufacturer, an automated guided vehicle (AGV) system

makes fully automated production safer and more efficient. As general contractor, KUKA was responsible for the

AGV system integration in the entire body shop: from the development of the safety concept, through planning,

engineering, simulation and project management. A milestone was set in the AGV supported production of vehicle

bodies.

Read More

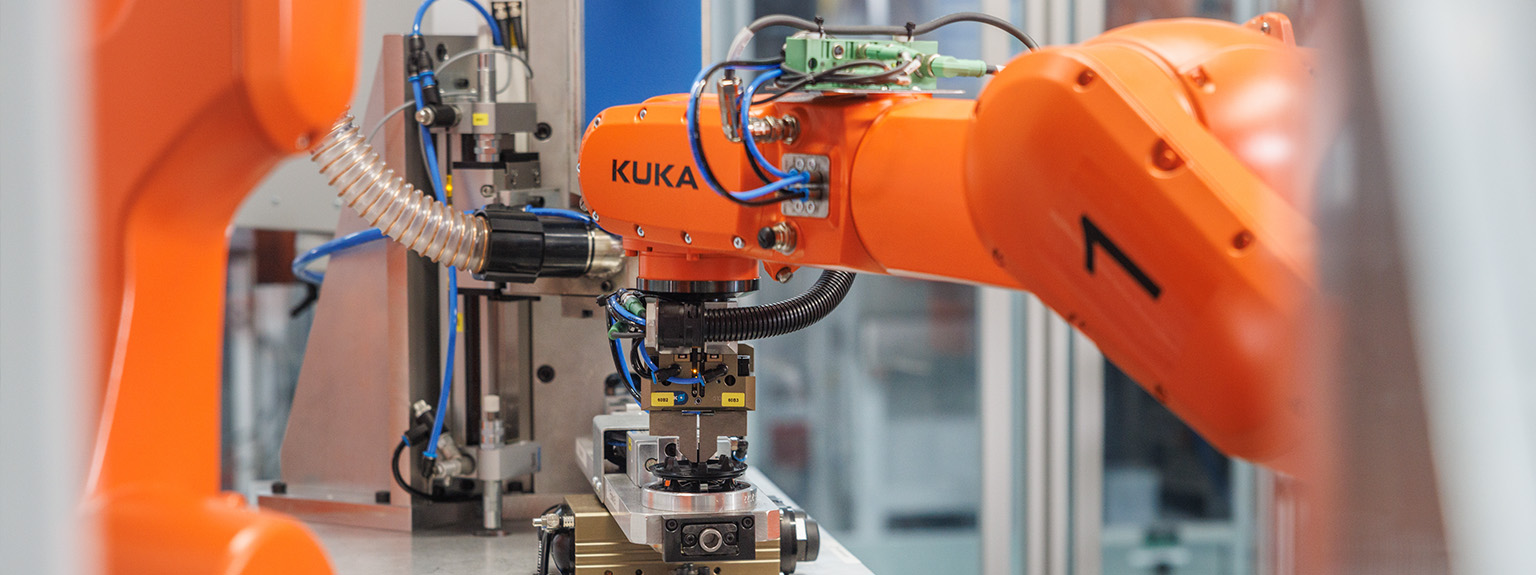

Fully automated leak test system

KUKA is implementing a fully automated test system for testing the oil and water cavity and the fuel rail in the

engine block. The BMW Group plant in Hams Hall, just outside Birmingham, UK, produces three- and four-cylinder

gasoline engines. The production also includes the machining of key engine components. Here, KUKA has

implemented a fully automated test system for testing two different engine generations.

Read More

maxon drives fly to the Red Planet with NASA's Perseverance rover

NASA’s fifth rover is on the way to Mars. Its main mission is to collect soil samples that will be analysed on

Earth later. The rover will also carry a helicopter that will perform the first flights on the Red Planet.

maxon's precision DC and BLDC motors will be used for numerous mission-critical tasks.

Read More

CONEC supports field robot project

In 2014, the collaboration between CONEC and the team of Kamaro‑Engineering began. Kamaro-Engineering e.V.

specializes in the development of field robots which enable new, environmentally friendly methods in

agriculture.

Read More

KUKA robots sort up to 3,000 blood samples per day

LT Automation and Intelligent Systems have developed a robotic system with transport boxes for automatically

checking and sorting blood samples at Aalborg University Hospital.

Read More

Mix it, Toni! Fully automatic bar system with rooftop bartender robot

Ice cubes. A shot of rum. Stir in the cola. Preferably add a slice of lime. And voilà: the Cuba Libre is ready.

But on the rooftop terrace of the TownHouse Duomo Hotel in Milan, the drink is not mixed by a bartender, but

rather by a robot. With “Toni”, a KUKA robot from the KR AGILUS series, visitors can order their drink via app –

and then enjoy it freshly prepared a few minutes later. “Toni” merely has a few problems with the small talk.

Read More

High-precision navigation for the smart factory

KINEXON implements intelligent navigation for driverless vehicles with the Kontron KBox. Industry 4.0 and the

Industrial Internet of Things are changing production and logistics processes in the long term. In the future,

objects will be networked and interact automatically in all areas. In order to guarantee smooth processes,

detailed position and status data must be generated and analyzed. KINEXON, located in Munich, Germany, has

developed KINEXON Brain, an intelligent solution based on an IoT...

Read More

Autonomous transport of goods in the factory

Two KUKA omniMoves automate the transportation of goods at Austria Metall AG (AMAG). The autonomous transport

platforms are responsible for the independent transportation of heavy aluminum plates and contribute greatly to

making the intralogistics more flexible. The omnidirectional platforms move autonomously and perform the final

production step independently.

Read More

Robot technology revolutionizes timber construction

Two KUKA KR 500 FORTEC robots manufacture innovative lightweight timber construction components for a pavilion

for the Bundesgartenschau. The ICD of the University of Stuttgart has developed the robotic manufacturing

solution in collaboration with system integrator BEC. Robotic solutions such as these have the potential to be a

game-changer for the timber construction industry, which has only made limited use of automated production

processes until now.

Read More

Origami with heavy-duty corrugated board

Origami – the art of paper folding originated in Japan and is known worldwide. The art of robot-based corrugated

board folding can be admired at Tricor Packaging & Logistics AG, which has its headquarters in the southern

German city of Bad Wörishofen. The company specializes in the construction of heavy-duty corrugated board and

packaging. And the highly productive and precise operation of the assembly machines can be credited to KUKA

Customer Service.

Read More

Fully automatic production line: A new era in frame manufacturing at MAGNA Presstec

Since 1979 it has been blazing a trail through woods and fields, mud, gravel and snow: the Mercedes G-Class. To

make this feasible, the manufacturer uses particularly stable ladder frames. These frames are built at MAGNA

Presstec in the Austrian town of Lebring near Graz. Since 2017, production of the facelift model has been

running fully automatically on a line from KUKA. Specialists from the two companies collaborated closely to

resolve various challenges,...

Read More

Bin picking – top speed and robust detection

Top speeds in scanning and parts detection are offering a whole new level of performance in fully automated bin

picking. The latest version of already proven IntelliPICK3D, now fitted an innovative four-camera sensor

solution enable robust component detection and optimized cycle times: ISRA VISION's wide range of sensor sizes

enables the detection of even the tiniest components in the millimeter range. Moreover, easy integration in just

a few hours allows maximum flexibility of utilization....

Read More

Mecademic started its 2019 world tour with ATX West

Less than three years after the Meca500, the probably smallest and most precise industrial robot arm, was

introduced to the market, more than a hundred manufacturers in the electronics, medical device, and automotive

industries use the robot to automate various testing and production operations.

Read More

These robots crawl into every nook and cranny

It started as a project by two engineers who were close to retirement. Today, the modular inspection robots by

Canadian company Inuktun are successfully in use all over the world – defying even the most adverse conditions.

Read More

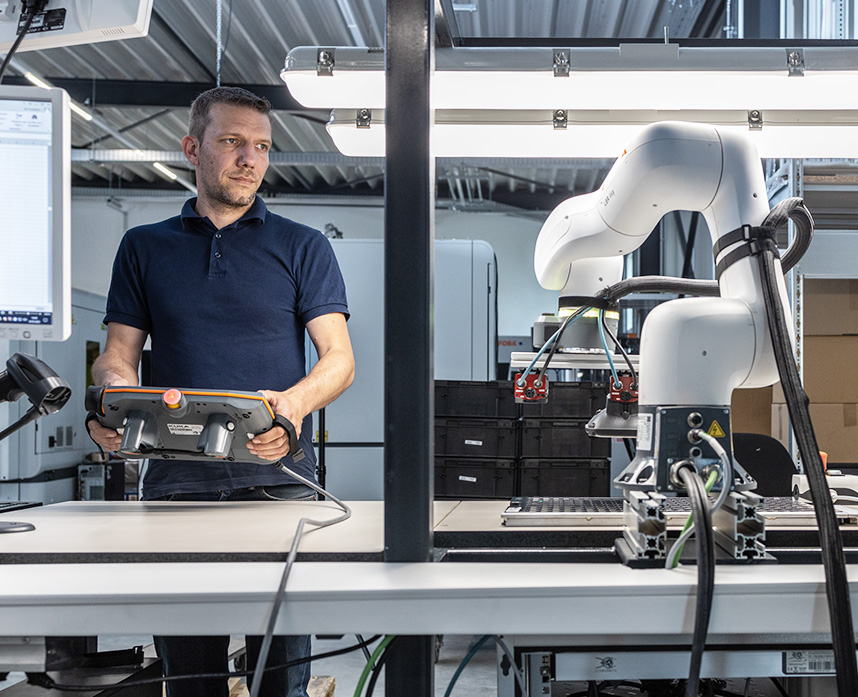

Smart optimization rather than investment

Numerous companies are sceptical, hesitating to take the step to digitalization. As an industry pioneer in the

area of I4.0 grippers and real-time simulation, Zimmer Group is ready to convert the few remaining doubters and

naysayers. The company now offers their customers integrated solutions (“digitalZ”) that are tailored to the

software platforms of the customers.

Read More

New Grippers with steel and aluminum linear guides

The Zimmer Group has added a new pneumatic model range to its technology-leading 5000 series of premium grippers

– in addition to the existing models with steel linear guides, versions with aluminum linear guides are now also

available.

Read More

Seventh Axis for robots

The concept of the seventh axis provides robot applications with an increased motion range. With the Seventh

Axis system from the Actuator System Line Rollon offers a practical solution for this task.

Read More

Robot systems: workpiece handling with vision

It started with a blank. But how does the workpiece get onto the line or into the machine? Depending on the

state it is delivered in, this task can quickly become very complex. Reliable 3D object detection systems

optically capture and evaluate data. Liebherr works with a variety of 3D vision systems to match the

requirements and smoothly handles the supply of every haphazardly stored part with process precision.

Read More